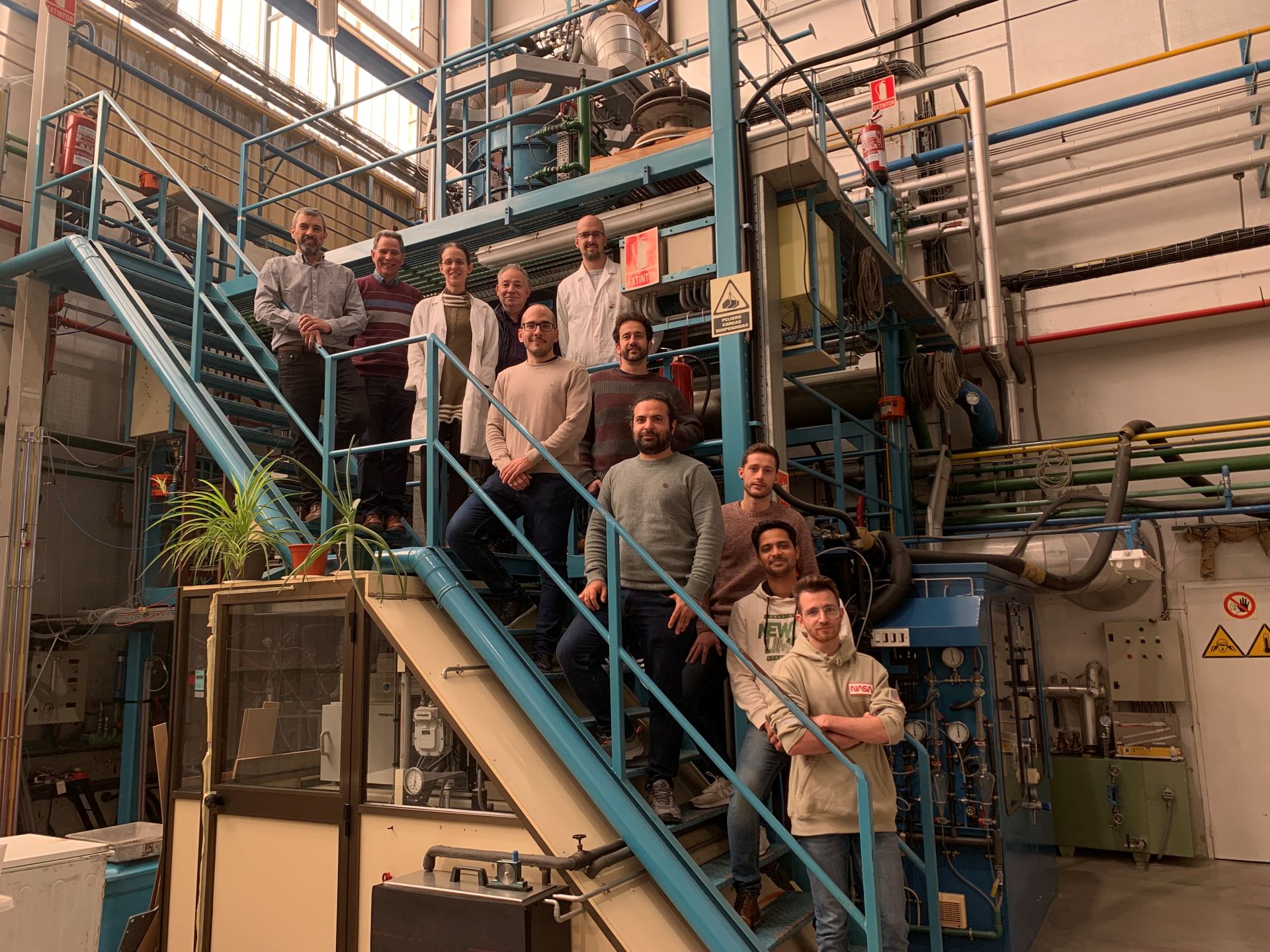

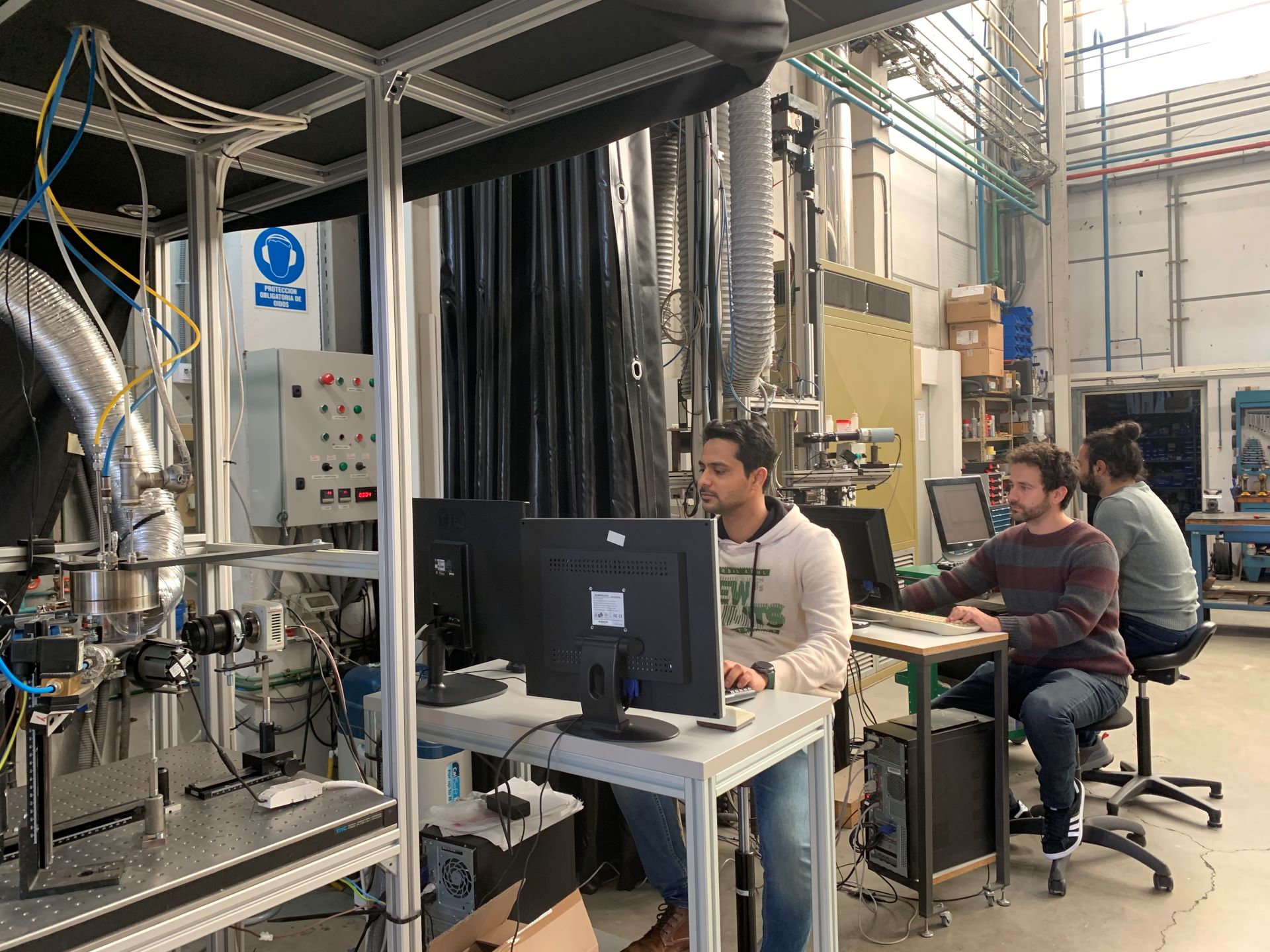

The Fluid and Energy Engineering Laboratory (LIFEn) became part of the I3A last year, within the Fluid Dynamic Technologies Group (TFD). More than 400 square metres house a set of experimental facilities for studying combustion applications and for testing fluid dynamic devices and systems, some of them a unique reference at national level.

More than 150 projects, contracts with companies and publicly funded research have passed through its facilities. Currently, the group has more than one million euros in funding granted in recent months in competitive calls for proposals and collaborations with companies.

Since its inception, LIFEn has addressed a wide variety of combustion applications, working on improving efficiency and reducing emissions with heavy fuel oil and pulverised coals, different low nitrogen oxide emission technologies, biomass and waste combustion, development of advanced flame monitoring and control methods, among others. They also carry out numerous projects on applied fluid dynamics, almost always in collaboration with companies in the energy, automotive, household appliances, gas and oil sectors.

Its activity dates back to 1988, when the Laboratory for Research in Combustion Technologies (LITEC) was created, promoted by Professor César Dopazo, as a national pioneering centre in the science and technology of combustion. It was a joint centre of the University of Zaragoza, the CSIC and the Government of Aragon until 2011, when it was renamed LIFTEC and ceased to be part of the regional government. It was not until last year that it ceased to be a joint CSIC-Unizar centre and LIFEn was integrated into the I3A.

Today, five lines of work are at the centre of its activity:

Hydrogen combustion

The use of hydrogen as an energy carrier and storage method for renewable energies is an essential element in the roadmaps towards a decarbonised economy. LIFEn has been studying different aspects of hydrogen combustion in both domestic and industrial applications for more than a decade. In addition to analysing flame characteristics under different designs and operating conditions, specific studies are carried out on instability phenomena and flashback problems.

Another line of work is the development of new methods of flame monitoring using sensors and artificial intelligence, as a promising way to detect changes in behaviour or to achieve a permanent adaptation of the equipment depending on the fuel composition.

Apart from collaborations with companies, these studies are carried out within the framework of a Knowledge Generation Project financed by the Ministry of Science and Innovation, 'Challenges for the efficient, clean and safe combustion of hydrogen and natural gas mixtures' and the Complementary Plan for Green Hydrogen and Energy, coordinated by Itainnova and in which the Aragon Hydrogen Foundation and other groups from the University of Zaragoza also participate. The NeoCC project plans to analyse the use of hydrogen mixtures, whether green or process by-products, in combined cycle plants.

Green hydrogen generation

In collaboration with an energy company, LIFEn is developing methods for the analysis of green hydrogen generation plants (SOPHiE, Simulation and Optimisation of green hydrogen plants), the first application of which is a plant supplying hydrogen for fertiliser production, considered to be the largest green hydrogen plant for industrial use in Europe.

This type of simulation tool is an essential support for plant management, facilitating the management and techno-economic optimisation of the operation of electrolysers and storage systems (hydrogen tanks and batteries) or the import of photovoltaic electricity or electricity from the grid.

New combined cycle operation strategies

In the short and medium term, combined cycle plants are expected to play an important role in the energy transition, as an essential complement to fluctuations in renewable energy generation and with the progressive incorporation of alternative fuels (e.g. green hydrogen or hydrogen from waste streams from other processes).

In this context, it is essential to promote new operating strategies and advanced monitoring solutions to achieve efficient and low-emission operation of the combustion equipment and the overall plant. For almost a decade, LIFEn has been actively collaborating with companies in the sector, which has already led to very notable advances and which will continue over the next three years in the NeoCC project (New combined cycle operation strategies for the energy transition), recently approved in the call for Public-Private Collaboration Projects.

Alternative liquid fuels

Apart from biodiesel or bioethanol, biokerosene seems to be the most viable option in the short term to decarbonise air transport, and liquid fuels can also be obtained by high temperature treatment (pyrolysis) of biomass, plastics or tyres or by-products such as process glycerine, among others. However, unlike conventional petroleum-based fuels, there is very limited knowledge about their behaviour in combustion equipment.

The aim of the studies carried out by LIFEn is precisely to generate new data for alternative fuels under conditions representative of real burners. Within the project "Analysis and optimisation of evaporation and combustion processes of residual and alternative liquids", a wide variety of liquids or the possibilities offered by their additivation with carbon nanoparticles or nanotubes to accelerate the combustion process are being analysed.

Applied fluid dynamics

Throughout its history, LIFEn has conducted numerous studies on the fluid dynamic behaviour of elements and systems in a wide range of applications, including automotive devices, gas installations and domestic equipment.

For example, the group is actively collaborating with BSH to study new induction hobs with integrated extraction system. LIFEn's facilities host tests on different designs and develop innovative solutions that, if successful, could be implemented in the coming years.

Also worth mentioning in this section is the group's activity during the pandemic to develop and raise awareness of ventilation and aerosol filtering as effective prevention measures, especially in high-occupancy areas such as classrooms, transport and hospitality.