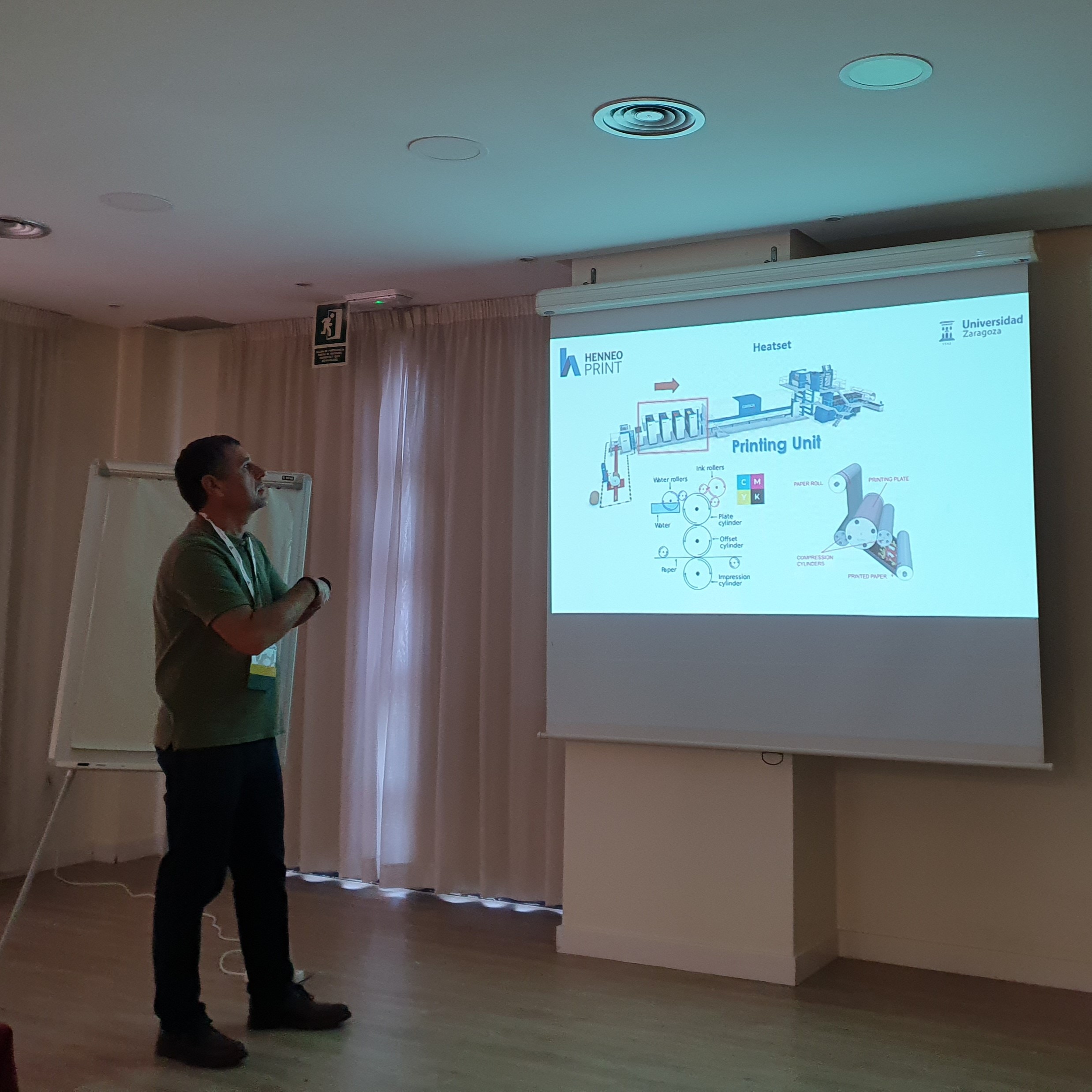

The SID (Distributed Information Systems) research group is participating in the development of an innovative platform that integrates technologies such as artificial intelligence, IoT and big data for the real-time management of Heatseat printing presses. This is an initiative promoted by the HENNEO group at the printing plant located in the Zaragoza town of Villanueva de Gállego, in collaboration with the technology consultancy Hiberus.

This comprehensive and pioneering system "significantly improves efficiency in this type of process and places the press at the forefront of the printing market", according to the company.

Researchers Eduardo Mena and Carlos Bobed, from the grupo de investigación SID have been part of the team that has developed this innovative platform.

The "Heat Seer" project has been carried out with European Union funding, which has enabled Henneo Print, the company that manages the facilities, to drive a transformation process in its internal operations through a project financed by red.es. State-of-the-art sensors have been incorporated into its presses to capture both machine performance information and specific information such as motor speed, component temperature and power consumed during operation. This data is integrated in an intelligent way, merging with data from the ERP system and the manufacturing system, which facilitates the plant's operational efficiency.

The software will enable more informed and strategic decision making and will enable the maintenance team to anticipate potential problems, perform predictive maintenance and reduce machine downtime. In addition, the plant now has the ability to perform job planning simulations based on the data collected. This not only improves resource allocation efficiency, but also allows for more accurate and flexible planning. It also provides the ability to measure performance through Key Performance Indicators (KPIs), so the plant can continuously evaluate and adjust its operations to achieve excellence.

The work being carried out was presented in the Congreso Internacional IARIA 2023, which was held in Valencia last November.

This project is funded by Red.es (Ministerio de Asuntos Económicos y Transformación Digital) in the 2021 call for proposals for research and development projects in artificial intelligence and other digital technologies and their integration into value chains, co-financed by the European Regional Development Fund (ERDF).